Our export quality steel shots enable preparing a single or multiple component surface by roughening it up by undergoing the process of abrasive blasting. It helps in increasing the bond strength of the components’ surfaces, application of coatings like primers and enamels or for metallisation, painting, powder coating, rubber bondage and more. Steel shots are spherical grains made of molten steel through an atomisation (granulation) process. These cast steel shots are available in different sizes and hardnesses.

A smooth, blemish-free high-glow surface is essential to achieve a glass-like finish. These are manufactured using silicon carbide abrasive combined with a very unique stearate coating. This significantly improves performance and finish by reducing friction and giving a gliding sanding action that results in a very consistent, scratch-free surface.

Applications:

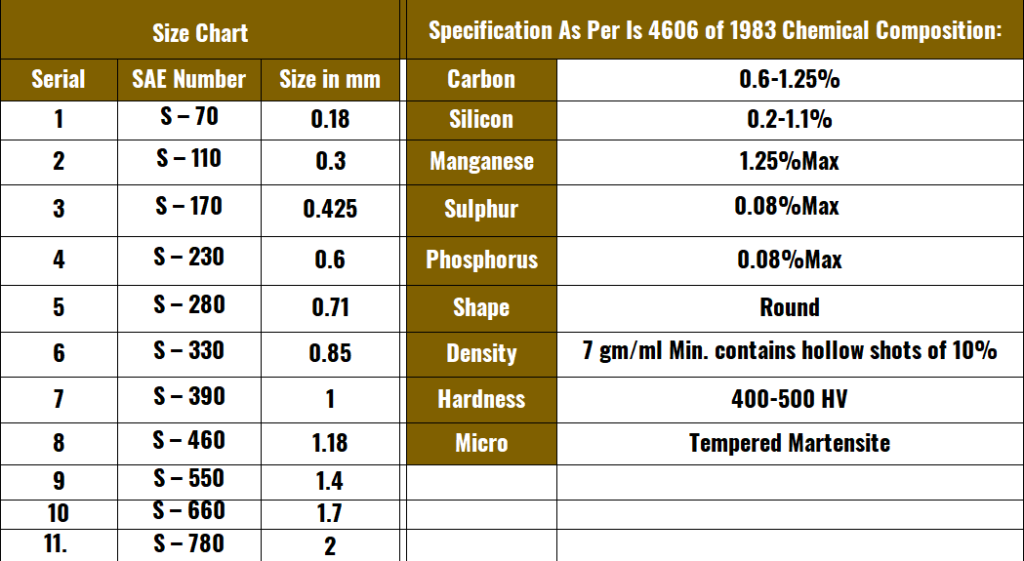

These are used in applications for components like castings, forgings, fabricated components, ferrous and non-ferrous components, etc. Blasting with steel abrasive media is an important operation at various stages of metal production. There are different varieties and sizes of steel shot which yield extraordinary results on the metal surface. A larger steel shot vigorously cleans a rougher surface. They produce the least amount of dust because their process is not harsh. Steel shots are used to clean heavy parts of metals such as engine turbine blades, crankshafts, and heavy-duty springs, etc. Low carbon steel shot has a low hardness in comparison to high carbon steel shot. Because of its microstructure, it resists impact while at the same moment it suddenly scatters/dissipates and turns into fine powdered dust. It is even used for flash descaling. Most steel abrasives are manufactured from high-carbon steel composition, the best compromise between mechanical and chemical properties, efficiency, and durability. The most vital properties of steel abrasives are hardness, size and shape, toughness and cleanliness. Steel shots for shot peening: Shot Peening is the repeated striking or injecting of a metal surface by hard-shot particles. These impacts produce deformation or change in the metal surface but also improve the durability or life of the metal surface. The media used in this process is spherical rather than triangular.

Steel Shot Features:

| Type | Shot |

| Material | Spheres Made From Cast High-carbon Steel |

| Shape | Spherical |

| Hardness | 7- 8 |

| Density | High |

| Surface Profile | Peening Effect, Creates A Smooth And Compacted Surface |

| Dust Generation | Low |

| Cost | Higher Cost |

| Color | Black |

| Applications | Automotive Manufacturing, Construction, Aerospace Industry |

| Used For | Surface Preparation, Polishing |

| Environmental Impact | Recyclable, Low Dust Generation |

| Safety Considerations | Requires Proper PPE For Blasting Operations |

| MOQ | As Per Requirement |

| Exporter By | National Enterprises |

| Country Of Origin | India |